COLOR MASTERBATCH MIXING IN PLASTIC MANUFACTURING

I. CHANGE OF COLOR MASTERBATCH

The effect of color masterbatch on injection molded plastic parts is complex. While rarely top of the list of issues to consider when planning a project, it should be addressed at the material selection stage. This process requires several important steps. Color resin selection will depend on factors including the actual resin involved and the end application, which may dictate durability needs, environmental factors and COLOR PLASTIC PRODUCTION costs.

Related properties of the resin include melt rate, melting or processing temperature, transparency, structure (crystalline or amorphous), and the reinforcing agents and fillers being used.

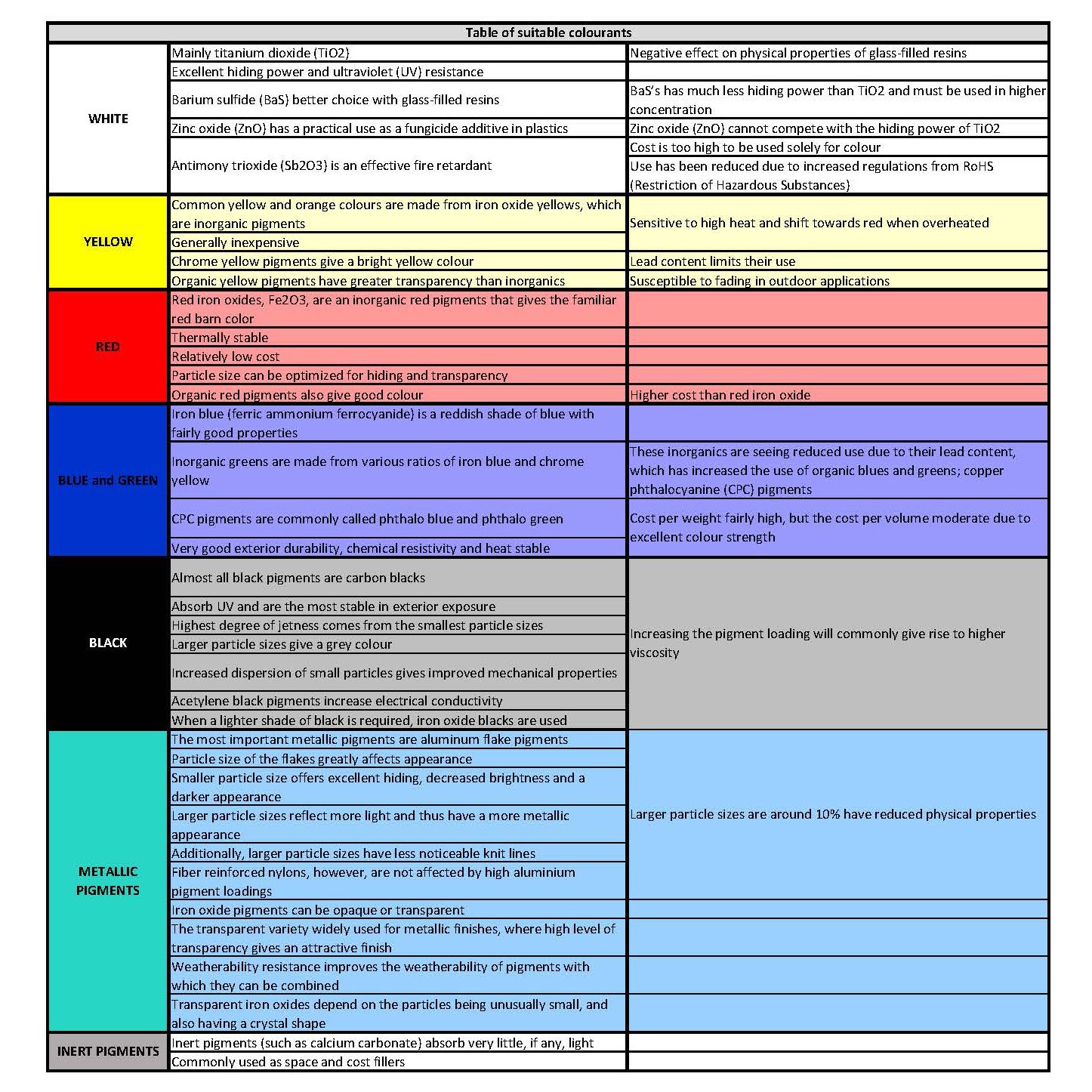

1. Pigment - Overall palette

Colorants/ color masterbatch can be dyes or pigments, or primary colors. Pigments do not dissolve into the resin, while dyes enter solution in the resin and are easily mixed. They are used to color transparent plastics and where strong tinting is required. Dyes give vibrant colors but do not blur surface imperfections as pigments do. Dyes also tend not to do well in outdoor applications.

1.1. Pigment:

Colorants can be partially soluble (organic) or insoluble (inorganic). Organic pigments are more efficient than inorganic pigments in terms of tinting ability and color fastness, producing brighter and more lustrous colors at a lower percentage (usually 0.2-0.5% as opposed to with about 2%). They can also be used to color transparent plastics. Inorganic pigments are less mobile than organic dyes and pigments, so they are used to color plastics that require high transparency. Inorganic pigments also have superior heat and weather resistance to both dyes and organic pigments. However, some disorganization is considered a health hazard and as a result, the industry is turning towards organic pigments.

II. The influence of colorants / Color masterbatch - Color palette in production

Adding a color masterbatch colorant to the resin can affect the properties of the resin part, so it is important to consider the compatibility between the chemistry of the polymer and the chemistry of the colorant. The influence of the colorant on the properties of the polymer is also dependent on the amount of the primary colorant.

Certain compounds in colorants can disrupt the chemical properties of the polymer and weaken its original properties, such as impact resistance. The high heat used in the injection molding process can also affect the extent to which the colorant affects the polymer. The primary color array of the pigment itself must also be able to survive high processing temperatures. An individual colorant may affect one polymer differently than another. Interactions between polymers and colorants can also be affected by other additives. For example, a polycarbonate that is not affected by a colorant may react differently to it when flame retardants are added.

There are also a number of different methods for coloring plastics, including mastering, blending, surface coating, and dry blending. The method used can affect the mechanical properties of the plastic. For example, in the synthetic method, pellets of natural color are mixed with a mixture of pellets with a high pigment content. Since most polymers do not tend to mix with other polymers, care must be taken to ensure material compatibility.

Different colorants can affect polymers in different ways. Transparent colors can be made with dyes that can affect the polymer structure less than the pigments used in opaque colors. Pigments are made from particles, and the size of those particles can affect the performance of the material. Therefore, casting the same part in different colors can result in different part sizes, which can be important if very tight tolerances are critical.

SUNRISE COLOURS VIETNAM CO., LTD

Add: CT2A Building, Gelexia Riverside Apartment, 885 Tam Trinh Street, Yen So Ward, Hoang Mai District, Hanoi City.

Phone: 0902224088 Fax: 0084 243 645 2586

Moblie/What'sapp/Wechat:

0902224088

Email: sales1@sunrisecolour.com

Website: http://sunrisecolour.com

Related posts

.png)